Superior technology & quality

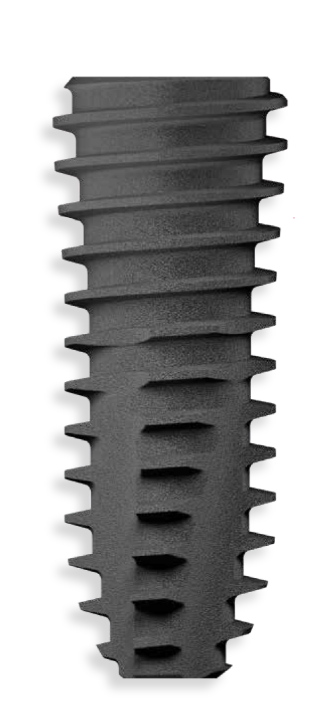

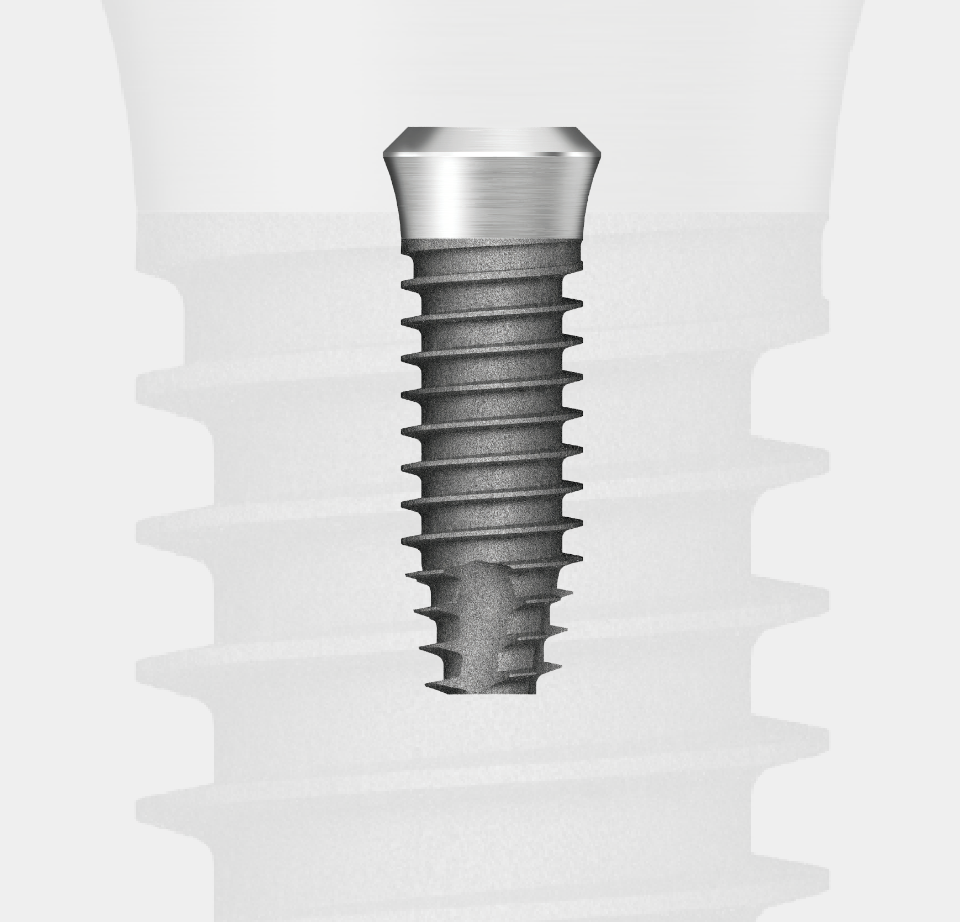

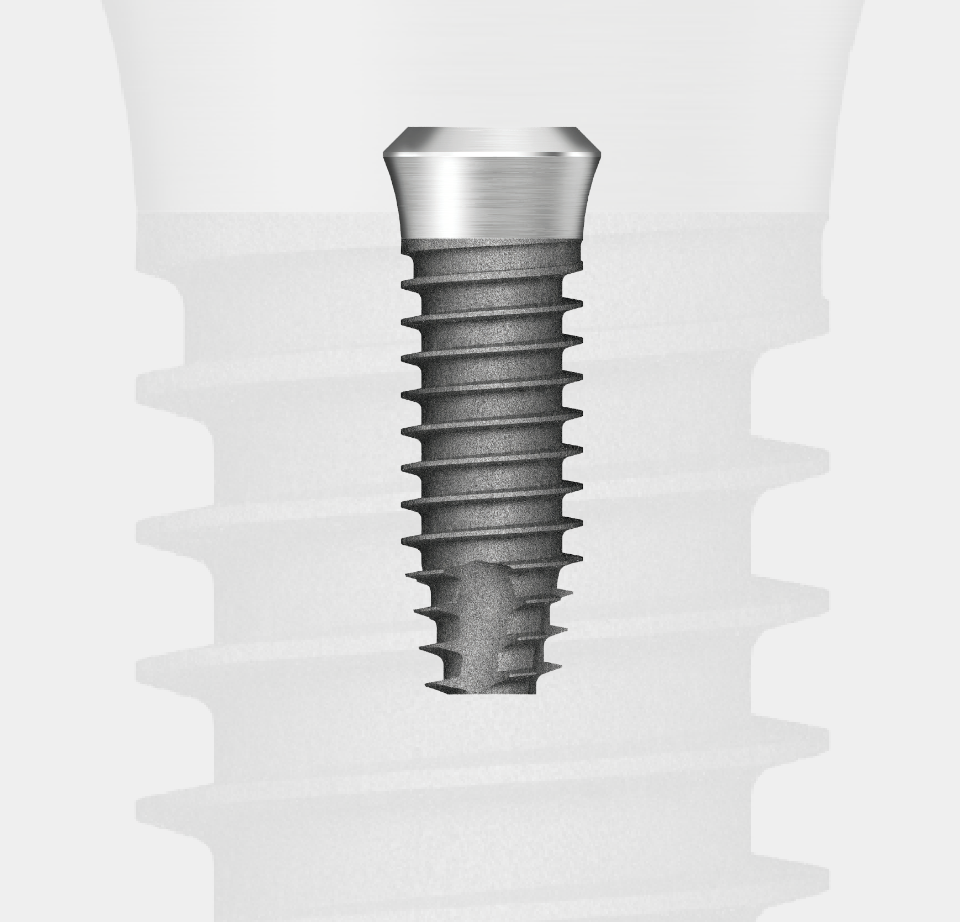

UF Implant

Internal Submerged System

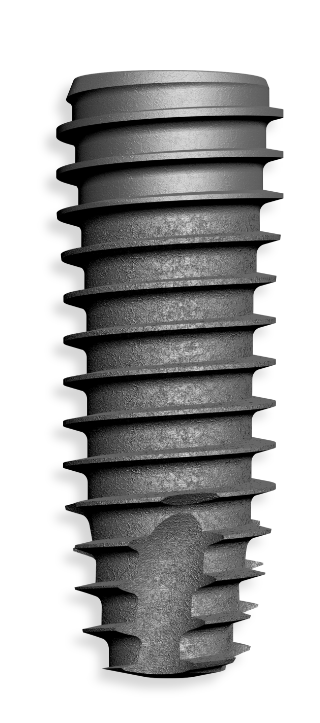

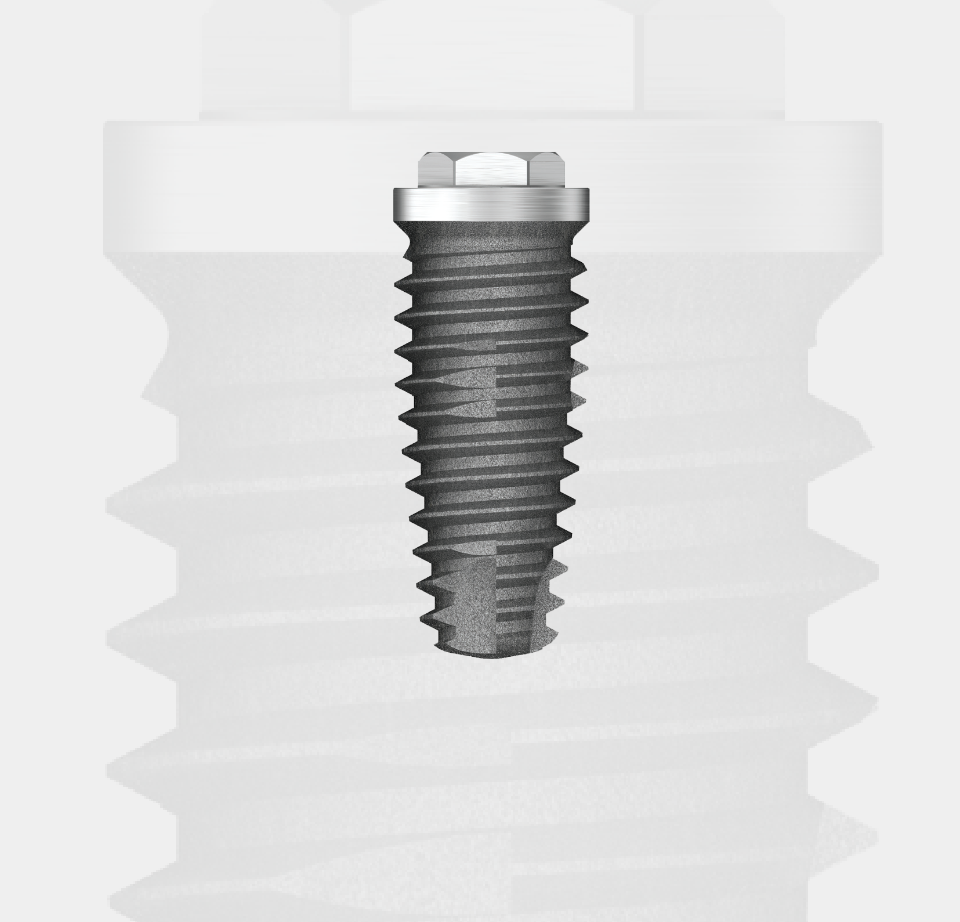

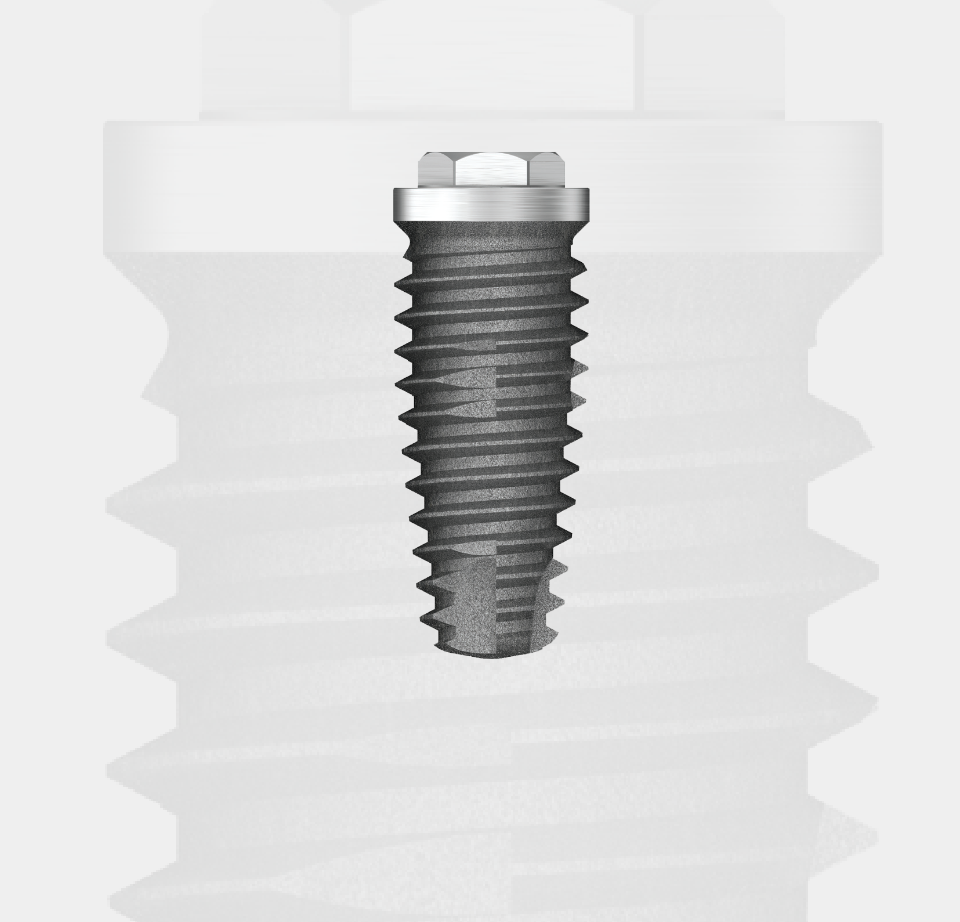

UFII Implant

Internal Submerged System

UFII Implant

Internal Non Submerged System

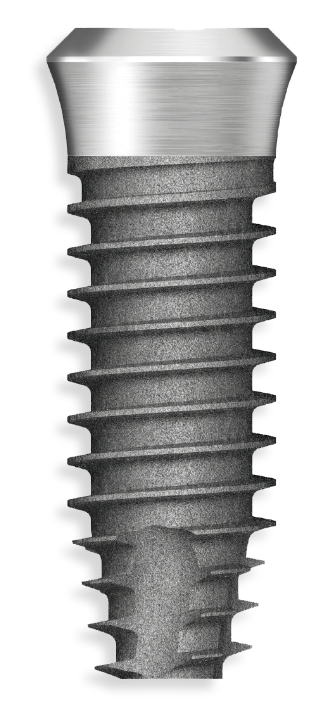

FTN Implant

External System

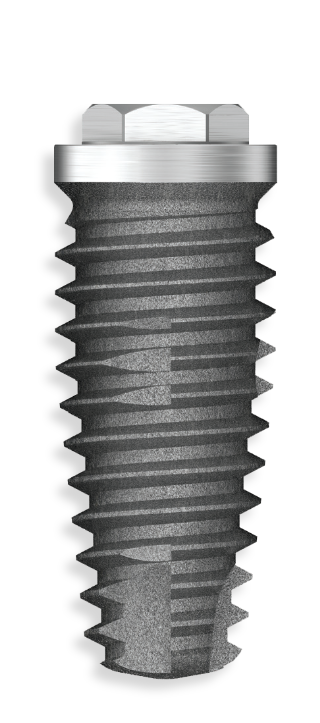

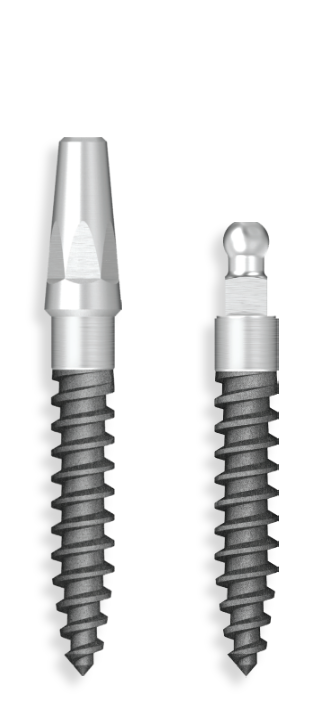

Protem Implant

Protem Onebody System

UV Active

UV Implant System

DIO IMPLANT

DIO IMPLANT SYSYEM

Signature Product

UFII Internal Submerged System

Open Thread

It is possible to adjust the implantation

depth by reducing the fixture

placement resistance.

Platform Switching

Since it has a platform switching

structure, stable prosthetic

connection is possible.

Upper Thread

Tapered Thread, Initial Fixation

By applying a tapered thread to the straight body,

the stress applied to the upper part of

the fixture is effectively dispersed.

The thread depth decreases upwards,

reducing friction on the cortical bone.

Morse Tapered Contact

Connection

Straight Body

Decrement of Bone Damage

The depth of the fixture is varied by changing

the depth of the body part,

and stable implantation is possible like

a straight type in a fixture with a long depth.

Cutting edge

Tapered Body

Taper Guide Gradually

Even with weak bone quality by

applying a taper, initial entry is

easy even when drilling is weak.

Apex

The gentle round shape can reduce

tissue damage caused by implants

when used in the maxillary sinus.

Surface Treatment Feature

Hybrid Sand Blast & Acid Etched

Surface of

a DIO RBM implant

Surface of

a DIO Hybrid SLA (HSA) implant

01

Internal Submerged System

03

External System

05

UV Implant System

360° Cylindrical UV Light completely surrounds

implant to achieve perfect hydrophilicity

02

Internal Non Submerged System

04

Protem IMPLANT

Protem Onebody System

Internal Submerged System

Internal Non Submerged System

FTN External System

Protem Onebody System

UV Implant System

Why are DIO Implant Special?

- 01

-

Widely used

worldwideWe manufacture state-of-the-art implants and provide treatment solutions used in more than 70 countries.

- 02

-

DIO issues a certificate of authenticity for each case.

We provide after-care services if you have placed a DIO implant